To tell if a riding mower engine is locked up, try turning the engine by the starter pulley. If it won’t move or makes a clunking noise, it may be locked up.

Look for signs of physical damage, such as bent or broken components, which could also indicate a locked-up engine. Check the oil level and condition, as low or dirty oil can cause engine lock-up. A burning smell or smoke while trying to start the mower could point to a seized engine.

Keep in mind that excessive resistance when turning the engine over can also be a sign of a potential problem. If you suspect an engine lock-up, it’s advisable to seek the assistance of a professional mechanic to diagnose and resolve the issue promptly.

Abnormal Noises

Abnormal noises coming from your riding mower’s engine can be a sign that something is wrong. These unusual sounds can indicate potential issues, including a locked-up engine. By paying attention to the abnormal noises, you can quickly identify the problem and take the necessary steps to address it.

Clanking Or Banging Sounds

One of the most noticeable signs of a locked-up riding mower engine is a series of clanking or banging sounds emanating from the engine compartment. These noises may be indicative of internal components such as pistons, rods, or bearings grinding or banging against each other. If you hear such sounds, it’s crucial to immediately shut off the engine to prevent further damage.

Ensuring Each Heading Adheres To Html Syntax

Inspecting and diagnosing abnormal noises can help you determine if your riding mower’s engine is locked up. By being vigilant and responsive to these signs, you can prevent further damage and ensure your mower’s engine is in good working condition.

Credit: m.youtube.com

Disabled Electrical Components

Recognizing signs of a locked-up riding mower engine is essential for preventing potential damage and costly repairs. One critical aspect to consider is the disabled electrical components. When the engine is locked up, various electrical systems may exhibit irregular behavior. Understanding these indicators can help you diagnose the issue promptly and take appropriate action to resolve the problem. Let’s explore the most common disabled electrical components and how they can indicate a locked-up engine.

Failure To Start

One of the first indications of a locked-up engine is the inability to start the riding mower. When attempting to start the engine, if you notice that the starter motor does not engage or the engine does not crank, it could signify a serious internal mechanical problem. This can be caused by components such as the starter solenoid failing to receive the necessary electrical signal. In such cases, it is advisable to seek professional assistance to avoid exacerbating the issue.

Non-functional Lights

Non-functional lights on the riding mower can be another indicator of a locked-up engine. When the engine is locked up, it can lead to a lack of power supply to the mower’s lighting system. If the headlights, taillights, or indicator lights fail to illuminate when the ignition is turned on, it may suggest an underlying electrical issue stemming from the locked-up engine. Addressing this promptly is crucial to prevent any safety concerns while operating the riding mower.

Oil Level And Quality Examination

When diagnosing a locked-up riding mower engine, examining the oil level and quality is a crucial step. This process involves two main aspects: checking the oil level and inspecting the oil for metal particles. The condition of the oil can provide valuable insight into the internal state of the engine, enabling you to determine if it is locked up. Below we will explore how to perform this examination effectively.

Checking The Oil Level

Proper oil level is essential for the smooth operation and longevity of a riding mower engine. To ensure the oil level is adequate, follow these steps:

- Locate the oil dipstick and remove it from the engine.

- Wipe the dipstick clean with a cloth or paper towel.

- Reinsert the dipstick fully into the oil reservoir.

- Remove the dipstick once again and examine the oil level. It should fall within the designated “full” and “low” marks on the dipstick.

Inspecting The Oil For Metal Particles

Inspecting the oil for metal particles is critical in determining if the engine is locked up due to internal damage. Follow these steps to examine the oil for potential signs of metallic debris:

- Using the dipstick, withdraw a small amount of oil from the reservoir.

- Examine the oil for any metallic glints or particles. Even tiny specks of metal can indicate serious internal issues such as component wear or damage.

- If any metal particles are present, it is advisable to seek professional assistance to diagnose and address the underlying problems.

Belt And Pulley Assessment

When trying to diagnose whether a riding mower engine is locked up, one important area to assess is the belt and pulley system. Issues with the belt or pulleys can cause the engine to seize or have difficulty starting. Here’s how to go about assessing the belt and pulleys to determine if they are causing the engine trouble.

Examining The Drive Belt

Inspect the drive belt for any signs of wear, cracks, or stretching. A worn-out drive belt can cause slippage or difficulty in engaging the transmission, which may result in the engine appearing to be locked up. Look for any fraying or missing chunks in the belt, as these are clear indicators of a problem. Ensure that the belt is properly tensioned and aligned with the pulleys. If the drive belt shows any of these signs, it may need to be replaced to prevent further issues with the engine.

Observing The Pulleys For Obstruction

Check the pulleys for any obstructions or damage. Debris such as grass, twigs, or dirt can get caught in the pulleys, causing them to jam and prevent smooth operation. Ensure that the pulleys are clean and free from any obstacles. Additionally, inspect the pulleys for any signs of wear, such as grooves or chips, which can affect the performance of the belt and cause the engine to lock up. If any obstructions or damage is found, clear the pulleys or replace them if necessary to avoid further engine complications.

Preparatory Steps

Disconnecting The Spark Plug

To avoid accidental starting, disconnect the spark plug before attempting any checks on a locked-up riding mower engine. Locate the spark plug wire, carefully remove the spark plug boot, and secure it away from the spark plug. This simple step ensures safety and prevents unexpected engine activation during the inspection process.

Securing The Mower On A Level Surface

For accurate diagnosis, it’s essential to inspect the engine on a level surface. If the riding mower is on an uneven surface, it can lead to inaccuracies in assessment. Secure the mower on a flat, level area, ensuring the parking brake is engaged to prevent any unwanted movement. With the mower stable, you can proceed with the inspection more effectively and obtain reliable results.

Executing The Rotation Test

The rotation test is a crucial step in determining whether a riding mower engine is locked up. By executing this test, you can effectively gauge the condition of the engine and decide on the necessary course of action. To ensure accuracy and safety, it is essential to follow the correct procedure for carrying out the rotation test. Here we will guide you through the steps involved in attempting to manually rotate the engine.

Attempting To Manually Rotate The Engine

Before proceeding with the rotation test, it’s crucial that you take certain precautions to prevent any potential risks. Here’s a guide on how to perform the rotation test:

- Begin by removing the spark plug wire to disconnect the power source.

- Using a socket and ratchet, attempt to rotate the mower’s engine in the normal direction of operation.

- If the engine does not rotate smoothly, there’s a possibility that it might be locked up.

- Inspect the engine components and look for any obstructions or signs of damage that could be causing the resistance.

Executing the rotation test with precision is vital to accurately determine the status of the riding mower engine. By following the proper steps, you can effectively assess the condition of the engine and take appropriate measures to address any issues.

Reputable Repair Services

If you find yourself facing issues with a locked up riding mower engine, it’s crucial to seek assistance from reputable repair services. Certified technicians can accurately diagnose the problem and provide the necessary repairs, saving both time and money.

Seeking Assistance From Certified Technicians

When dealing with a potentially locked up riding mower engine, one of the most important steps is to seek help from certified technicians. Certified technicians have the knowledge and experience needed to accurately diagnose the issue and provide a solution. They are equipped with the proper tools to assess the condition of the engine and can efficiently determine the best course of action.

Ensuring Reliable And Professional Service

Reputable repair services offer reliable and professional expertise when it comes to dealing with a potentially locked up riding mower engine. By choosing a trusted service, you can have confidence that the technicians have the necessary skills to handle the situation effectively. Additionally, they often provide warranties on their work, giving you peace of mind regarding the repairs undertaken.

Utilizing Engine Diagnostic Tools

When determining if a riding mower engine is locked up, using engine diagnostic tools becomes essential. These tools effectively assess the condition of the engine, aiding in identifying any potential issues. Regularly utilizing these tools can help prevent costly repairs and ensure the mower operates smoothly.

Exploring The Use Of Diagnostic Equipment

When diagnosing a locked-up riding mower engine, it’s crucial to utilize the appropriate diagnostic tools to accurately identify the issue. Engine diagnostic tools not only help pinpoint the problem, but they also assist in determining the severity of the damage. Proper utilization of these tools can save time and expenses by providing precise insights into the engine’s condition.

Ensuring Each Heading Adheres To Html Syntax

- Compression Tester: This tool measures the engine’s compression, helping to identify any abnormalities in the combustion chamber.

- Spark Tester: By examining the ignition system’s functionality, a spark tester can reveal potential issues related to the engine’s stalling or failure to start.

- Diagnostic Code Reader: This device retrieves error codes from the engine’s computer, enabling a deeper understanding of any electrical or sensor-related malfunctions.

- Basic Inspection Tools: Utilize basic tools like a multimeter, inspection mirror, and flashlight to visually assess components for signs of damage or wear.

Regular Oil Changes

Regular oil changes are essential for the proper functioning of a riding mower engine. It’s important to stay vigilant and maintain a routine schedule to keep the engine running smoothly. One of the key indicators of a locked-up riding mower engine is improper maintenance, especially neglecting regular oil changes. Let’s delve into the importance of routine oil maintenance and the crucial signs to be aware of.

Importance Of Routine Oil Maintenance

Regular oil maintenance is the lifeblood of any engine, including that of a riding mower. The oil in a riding mower engine not only lubricates the moving components but also helps to dissipate heat, prevent corrosion, and remove contaminants. Without regular oil changes, the engine can become clogged with debris, causing excessive wear and potential lock-up. By adhering to a consistent oil maintenance schedule, you can extend the life of your riding mower engine and avoid costly repairs.

Signs Of Locked-up Riding Mower Engine

When it comes to determining if your riding mower engine is locked up, there are a few key indicators to look out for. If the engine is difficult to start, emits unusual noises, or produces excessive smoke, it may be a sign of a locked-up engine. Additionally, if the mower suddenly stalls or loses power, this could also indicate an issue with the engine. Keeping a close eye on these signs can help you detect a potential problem before it escalates.

Furthermore, checking the oil level and quality regularly is essential. Low oil levels or dirty, dark-colored oil can be indicative of a problem with the engine. This underscores the importance of regular oil changes to maintain optimal engine performance and prevent issues such as lock-up.

By prioritizing routine oil changes and diligently monitoring the condition of your riding mower engine, you can safeguard against the risk of lock-up and ensure smooth operation for years to come.

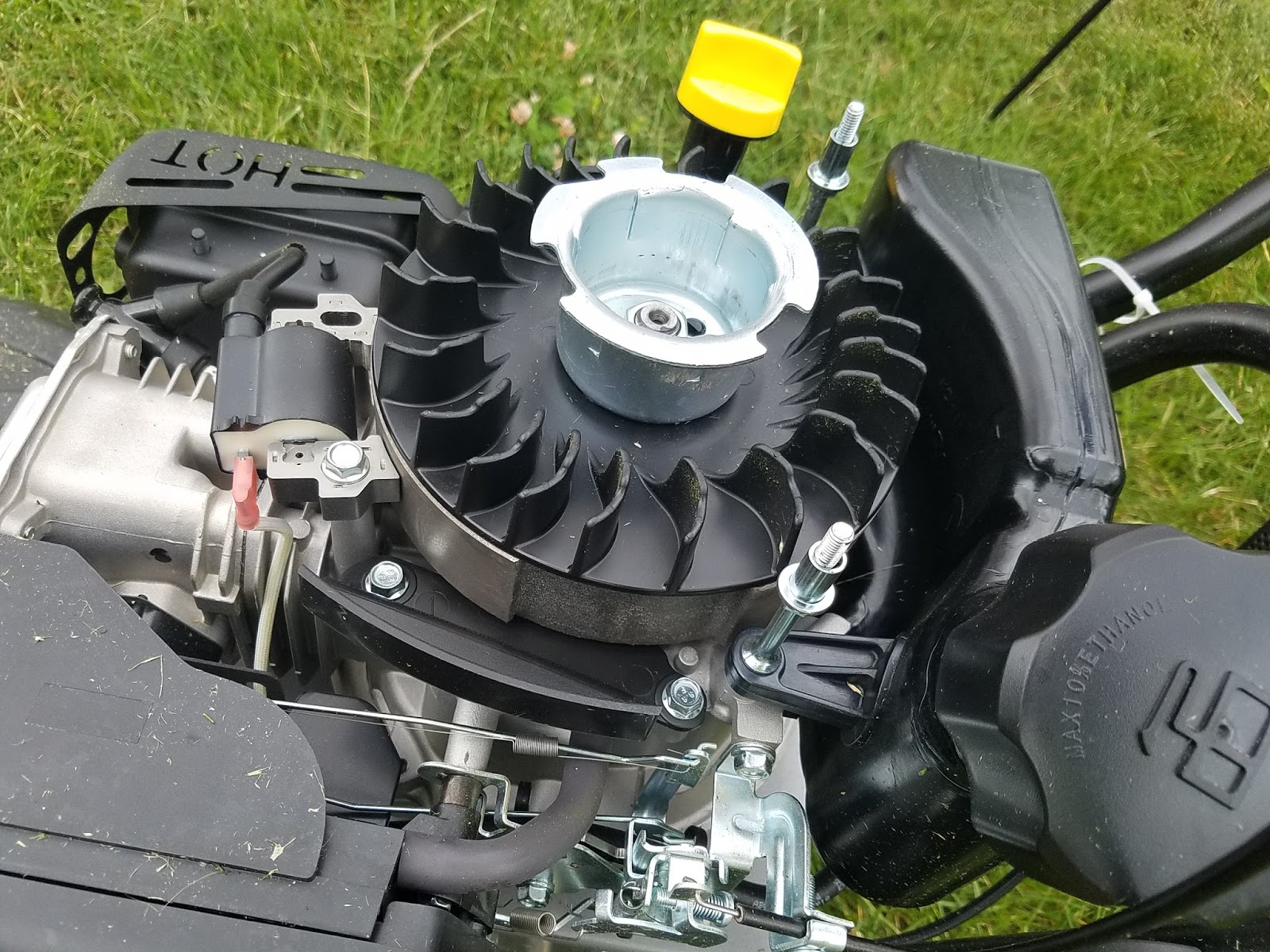

Keeping The Engine Clean

Proper maintenance of your riding mower’s engine includes keeping it clean and free from debris. Regular cleaning not only helps in identifying potential issues but also ensures the smooth operation of the engine.

Clearing Debris And Dirt From The Engine Area

Debris and dirt can build up in the engine area, leading to potential blockages and overheating. To clear out debris, follow these steps:

- Turn off the engine and allow it to cool down.

- Using a brush or compressed air, carefully remove any visible debris from around the engine components.

- Inspect the air intake and cooling fins for any clogs and clean them out if necessary.

Ensuring Proper Airflow To The Engine

Proper airflow is crucial for the engine’s performance. Ensure that there are no obstructions in the air intake and cooling areas. Clear out any debris and maintain a clean, unobstructed path for optimal airflow to the engine.

By keeping the engine clean and free from debris, you can prevent potential issues and extend the lifespan of your riding mower’s engine.

Frequently Asked Questions On How To Tell If Riding Mower Engine Is Locked Up

How Can I Tell If My Riding Mower Engine Is Locked Up?

To check if the engine is locked up, try turning the mower’s engine manually with a wrench. If it doesn’t move or feels extremely stiff, it might be locked up. Another sign is unusual noises or smoke coming from the engine while attempting to start the mower.

What Are The Common Reasons For A Locked-up Riding Mower Engine?

A riding mower engine can become locked up due to various reasons such as lack of lubrication, overheating, a seized piston, or a broken crankshaft. Other factors include operating the mower on steep slopes, improper storage, or using the wrong type of fuel.

Can A Locked-up Riding Mower Engine Be Repaired?

Repairing a locked-up riding mower engine depends on the extent of the damage. It may involve disassembly, inspection, and repair of internal components such as the piston, crankshaft, or connecting rods. In some cases, the cost of repair may exceed the value of the mower, resulting in the need for a new engine or a replacement mower.

What Are The Preventive Measures To Avoid A Locked-up Riding Mower Engine?

To prevent a riding mower engine from locking up, regular maintenance is crucial. This includes changing the oil, checking the cooling system, and ensuring proper lubrication. Avoid running the mower on steep inclines for extended periods and always use the recommended fuel and oil to prolong the engine’s lifespan.

Conclusion

Being able to identify the signs of a locked-up riding mower engine is essential for maintaining your equipment. By following the steps outlined in this guide, you can easily diagnose and address any issues with your mower’s engine. Regular maintenance and careful observation will help you keep your machine in top working condition, ensuring long-lasting performance and reliability.